EASL benefits

Advantages of EASL DMD™ products

As far as it is known, there is no one technology that offers the same potential development ladder and multi-facetted applicability as EASL. There is, however, certain technologies that are competitors within specific application areas as regards to a limited number of the properties of EASL – most notably in the flat panel display industry are technologies such as electrophoretic (E-ink) and Cholesteric Liquid Crystals (ChLD) and, to a lesser degree, in the functional windows and facade materials industry (e.g. Electrowetting HEOS Displays & PDLC).

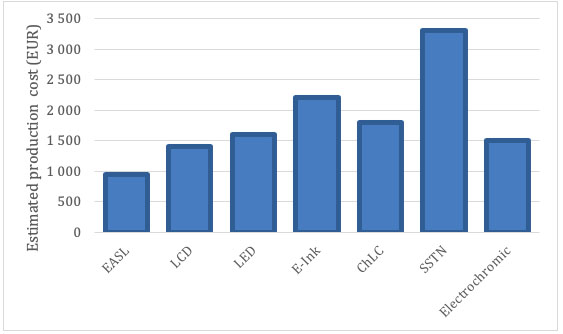

EASL is superior to alternative technologies in terms of EASL Daylight Memory Displays (DMD) can be read in direct sunshine, have up to 98% less energy consumption (EASL DMD displays only need energy to change any “given molecular state”), have significantly better robustness, have an unsurpassed transparency up to 90%, almost no haze (less than 3%), better readability in ambient light at wide viewing angles (180°), have better size scalability, read back to control centre, and have a better overall high volume production economics as indicated by the internal estimates in the graph below for end products in 1sqm @ 1,000,000 units per year.

Overall, the EASL technology has significantly better price/performance than all other competing technologies, regarding production, operation and total energy and environmental footprint. The EASL technology and its properties open up for a new level of profitability in an environmentally friendly business.

High light efficiency

Exceptional transmission of almost 90% (comparable to a window pane) opens up for new products, applications and solutions.

The transparency of the EASL DMD TM offers, in its light transmitting state, possibilities to produce “dynamic window” application (VindaugeTM), where the image seemingly appears from nowhere in a window embedded display, as well as implementing private windows features, where the light scattering state makes it impossible to see objects behind the window. This distinguishes the EASL based ID-modules from any other display technology.

Liquid Memory = zero power consumption

Conserve energy and increase operational time

The “Liquid Memory” attribute of EASL DMDTM products and solutions permits image retention without any power. Power is only needed when changing a part of or the whole image. This attribute dramatically reduces the power consumption when the display is updated infrequently, thus offering unprecedented energy savings in many applications and enabling development of energy efficient products. Image retention without power is indefinite and there is no risk of image burn-in, ghosting or other artefact common for other display technologies

Excellent readability even in 180 degrees and direct sunshine

Paper like readability in most lightning conditions and almost 180 degrees horizontal and vertical viewing angle

The reflective attribute of EASL DMDTM offers excellent readability even in direct sunlight. Light scattering nature of the smectic liquid crystal and the absence of polarizing filters provide superior wide-angle viewing at angles approaching 180-degrees an assure virtually no contrast loss at any direction as the viewing angle approaches the plane of the display. With a contrast ratio as high as !:20 and a peak diffuse reflectance approaching 30% of incident light, you will not find any LCD that performance better in direct sunlight.

Inherently white, grey levels and colour possibilities

Operates with natural white light

Light transmission and scattering in EASL DMDTM is wavelength independent, providing the image with natural white appearance. The image can be turned into black and white or single/dual colour by changing the display’s background and/or using special dyed smectic liquid crystals. Grey levels are zero power stable. Full colour EASL displays are under development.

Low production cost and high yield

Simplicity reduces the number of production steps

EASL DMDTM products can be manufactured on current production lines for passive matrix flat panel displays, thus avoiding major investments. The simplicity of the display´s structure, reduced amount of production steps and exploiting cost effective passive matrix addressing give clear advantages over competing technologies. In addition, it opens up for the possibility to use exciting production facilities globally. Apart from the proprietary smectic liquid crystal the relatively few components needed to produce the generic ID-modules are of industry standard.

Distinct voltage threshold

Allows for extremely high resolution displays

This feature tighter with the liquid memory of EASL DMDTM technology allows for development of extremely high resolution displays with cost effective passive matrix addressing.